1.The device (T44QK 6*1800 Cut to length line)is automatic and used to decoil, flattening and cutting steel coil to certain dimension. After boards head feed into flattening machine, other actions are controlled automatic by the data of speed, cutting length, cutting number and so on, which is input from touch screen.

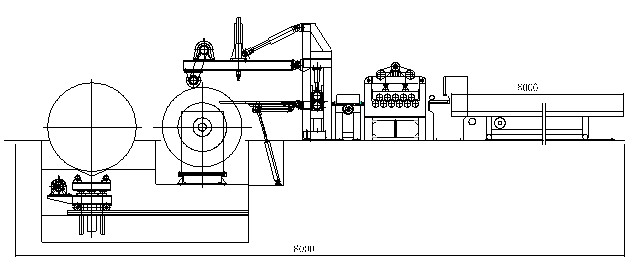

2.Production line technological process as follows:

Coil loading → decoiling → plate leading → leveling → plate storage → correct and centering → leveling → sizing → cutting → stacking

3.This line is centralized controlled by PLC, control console has the function of length setting, digital display, automatic counting, continuous cutting, failure warning and so on. The line arranged compact, sizing of plate use import servo motor, with high sizing precision.

1. Main technical parameter

1. Raw material:

| 1 | coil material: | Cold rolled steel plate, acid pickling plate (σs ≤ 260MPa, σb ≤ 450Mpa) |

2. Coil size

| 1 | thickness: | 2-6mm |

| 2 | width: | 800-1800mm |

| 3 | Sizing length | 1000-14000mm |

| 4 | Plate stack weight | 10 ton |

| 5 | coil inner diameter: | Φ610mm, Φ760mm |

| 6 | coil out diameter: | Φ1000-2000mm |

| 7 | coil inner weight: | ≤25 tons |

1. Speed and precision

| 1 | speed | 0-19m/min |

| 2 | Sizing error | ±1mm/ 2m |

| 3 | diagonal error | ±1.5mm/ 2m |

| 4 | Flatness | 2.5mm/m2 |

2. General data

| 1 | Power: | |

| Voltage | 380V±10% | |

| Frequency | 50Hz | |

| Installed capacity | About 70KW | |

| 2 | Environment conditions: | |

| Temperature | -5—40℃ | |

| Humidity | 80% | |

| Elevation | Below 1000M | |

| 3 | Protection grade | Electrical control cabinet, console IP54 |

| 4 | Air pressure | 0.6MPa |

| 5 | Air demand | 1m3/min |

| 6 | Layout size(L*W) | 26*6M |

| 7 | Elevation of working surface | +900mm |

3. Equipment structure and function

(1). Loading trolley

Use four column type hydraulic lifting, with strong capability of anti deviated load. Adopt motor and reducer to transmit the power, it walk smooth and steady.

(2). two-cone no harmomegathus type decoiler

1. Use two-cone no harmomegathus type.

2. Main decoiler shaft composed by motor, chain, clutch and brake, it can do decoiling both active and passive.

3. left-right decoiler move along the the base(both of single acting and linkage are available). They are driven by each hydraulic cylinder.

(3). plate leading device

It is used to flat the head of plate, then guide it into leveler with decoiler.

This device composed by guide press roll, bent beam, shovel head, and feeding support plate. Guide roller press plate head, press down or uplift by oil cylinder swing, rotate by the motor. Oil cylinder push the layer board, cooperate with bending beam to flat the head. According to different diameter of roll, shovel head stretch by oil cylinder, move the plate head away, after shovel head back, decoil can be taken.

(4) Correct and centering machine

Prevent plate running deviation, regulate the sheet into the leveling machine, in both sides of the sheet width direction with vertical guide roller, the guide roller frame fixed to the respective carriage, through the hand wheel, wire Rod adjustment by the screw nut so that the slide in the guide column along the width direction of the plate to accommodate different width.

(5). 11 rollers straightening machine

To flat steel plate.

1. Host machine: after plate fed into leveler, 11 pieces (upper 5, lower 6) of rolls leveling the plate. The gap between upper and lower rolls can be adjust by motor reducer, with good level effect.

In the center of straight roll, there use 3 sets of supporting roll to assist, to ensure the rigidity of working roll. Use centralized grease lubrication, with reliable lubricate effect.

11 pieces of leveling roll are use the material 9Cr2Mo, entirety tempering, surface hardening, surface hardness 62-65HRC. 39 pieces of support roll use alloy steel, heat treatment and hardening.

2. Transmission mechanism: use DC motor to drive reducer, gear distribution box, 11 pieces of cardan shaft make each roll working active. The material of gear is excellent carbon steel, heat treatment: tempering, surface hardening.

A. Technical parameter

Thickness: 2-6mm (σs<260MPa)

Width: 1800mm

Leveling roll: 11 pieces

Diameter of roll: φ160mm

Flatness error: ≤2.5mm/m2

(8). Shears (pneumatic clutch)

Adopt pneumatic clutch shears, with the fast speed. The blade can be adjusted simply, to adapt different plate with different thickness.

(7). plate discharge car (side discharge, back discharge)

Used to storage the stacking plates, convenient to packing and carry the plates.

It is composed by car frame, wheel, motor reducer, chain transmission mechanism and so on. One car run backward, another run sidewise, take turns, to increase efficiency.

(8). Hydraulic system

Composed by hydraulic pressure station, joint, oil tube, valve and oil cylinder.

The hydraulic system control the whole production line of oil cylinder action. Main hydraulic valve use imported product.

(9). Pneumatic system

Be made up of gas source, connectors, gas tube, valve, cylinders and so on. (Gas source provided by user)

Pneumatic system controls the operation of the cylinder of the entire production line.

(10). Electrical system

Achieve full range of motion control.

System has a console, control cabinet, centralized control across the board. The main console has a length setting, digital display, automatic counting, high and low speed adjustment, manual feed continuous shear failure alarm function. Length control system, speed control system, program controller(PLC), all from joint venture of imported products.