|

Project |

Parameter |

Project |

Parameter |

|

Voltage (V/Hz) |

380V/50Hz |

Heating method |

Electric heating |

|

Effective heating dimensions (mm) |

2200X1100 |

Installed total power (Kw) |

10 |

|

Temperature control |

130℃±2℃ |

|

|

|

Temperature control mode |

PID automatic temperature control, with over-temperature alarm system |

||

|

Equipment dimensions (mm) |

2400X1300X900 |

Total Weight(Kg) |

1000 |

|

Project |

Parameter |

Project |

Parameter |

||

|

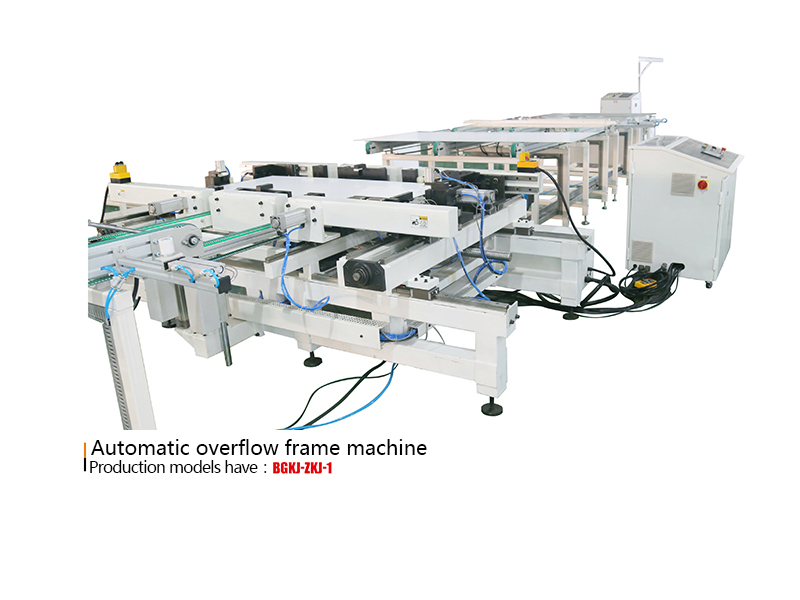

Voltage |

(V/Hz)380/50 |

Work efficiency |

1 block / (38 seconds) |

||

|

Aluminum frame height |

3300-50(mm) |

Work table height |

(mm)900±50 |

||

|

Maximum group frame dimensions |

2000X1100X(30-50)mm |

Group box precision |

The difference in edge size is ± 0.5mm Diagonal size difference ± 1.0mm |

||

|

Minimum group frame dimensions |

1300X800X(30-50)mm |

||||

|

Working pressure |

0.6Mpa~0.8Mpa |

||||

|

Installed total power |

(kw)7 |

Whole line weight |

(kg)3400 |

||

|

Equipment model |

BGKJ-22001100m |

Laminated area |

2.2m×1.1m |

|

Dimensions |

2600mm×1700mm×1400m |

equipment weight |

4T |

|

power supply |

380V 3 phase 5 lines |

Peak power consumption |

33KW |

|

Vacuum pump rate |

30L/S |

Normal working power consumption |

9KW |

|

control method |

automatic / manual |

Ultimate vacuum |

20Pa |

|

heating method |

SD320 heat transfer oil heating |

Temperature control mode |

Self – tuning intelligent PID control |

|

The highest temperature of the table |

180℃ |

Temperature uniformity |

± 1.5 ℃, multi-point temperature control |

|

Operating temperature range |

Room temperature ~ 165 ℃ |

Temperature controllable accuracy |

≤±1℃ |

|

Equipment model |

BGKJ-22002200m |

Laminated area |

2.2m×2.2m |

|

Dimensions |

2850mm×2600mm×1400m |

equipment weight |

5T |

|

power supply |

380V 3 phase 5 lines |

Peak power consumption |

38KW |

|

Vacuum pump rate |

30L/S |

Normal working power consumption |

15KW |

|

control method |

automatic / manual |

Ultimate vacuum |

20Pa |

|

heating method |

SD320 heat transfer oil heating |

Temperature control mode |

Self – tuning intelligent PID control |

|

The highest temperature of the table |

180℃ |

Temperature uniformity |

± 1.5 ℃, multi-point temperature control |

|

Operating temperature range |

Room temperature ~ 165 ℃ |

Temperature controllable accuracy |

≤±1℃ |

|

Equipment model |

BGKJ-22001100Q |

Laminated area |

2200*1100 |

|

Dimensions |

8.6m×1.7m×1.4m |

equipment weight |

4.5T |

|

power supply |

380V 3 phase 5 lines |

Peak power consumption |

33KW |

|

Vacuum pump rate |

15L/S |

Normal working power consumption |

11KW |

|

control method |

automatic / manual |

Ultimate vacuum |

20Pa |

|

heating method |

SD320 heat transfer oil heating |

Temperature control mode |

Self – tuning intelligent PID control |

|

The highest temperature of the table |

180℃ |

Temperature uniformity |

± 1.5 ℃, multi-point temperature control |

|

Operating temperature range |

Room temperature ~ 165 ℃ |

Temperature controllable accuracy |

≤±1℃ |

|

Equipment model |

BGKJ-28502200Q |

Laminated area |

2850*2200 |

|

Dimensions |

10.60m×3.25m×1.9m |

equipment weight |

9.5T |

|

power supply |

AC380V3 phase 5 lines |

Peak power consumption |

48KW |

|

Vacuum pump rate |

100m3/h |

Normal working power consumption |

18KW |

|

control method |

automatic / manual |

Ultimate vacuum |

20Pa |

|

heating method |

SD320 heat transfer oil heating |

Temperature control mode |

Self – tuning intelligent PID control |

|

The highest temperature of the table |

180℃ |

Temperature uniformity |

± 1.5 ℃, multi-point temperature control |

|

Operating temperature range |

Room temperature ~ 165 ℃ |

Temperature controllable accuracy |

≤±1℃ |

|

Equipment model |

BGKJ-22002200Q |

Laminated area |

2200*2200 |

|

Dimensions |

8.6m×3.2m×2m |

equipment weight |

7T |

|

power supply |

380V 3 phase 5 lines |

Peak power consumption |

40KW |

|

Vacuum pump rate |

30L/S |

Normal working power consumption |

16KW |

|

control method |

automatic / manual |

Ultimate vacuum |

20Pa |

|

heating method |

SD320 heat transfer oil heating |

Temperature control mode |

Self – tuning intelligent PID control |

|

The highest temperature of the table |

180℃ |

Temperature uniformity |

± 1.5 ℃, multi-point temperature control |

|

Operating temperature range |

Room temperature ~ 165 ℃ |

Temperature controllable accuracy |

≤±1℃ |

|

Equipment model |

BGKJ-36002200Q |

Laminated area |

3.6m×2.2m |

|

Dimensions |

12m×3.1m×1.8m |

equipment weight |

11T |

|

power supply |

AC380V3 phase 5 lines |

Peak power consumption |

68KW |

|

Vacuum pump rate |

70L/S |

Normal working power consumption |

20KW |

|

control method |

automatic / manual |

Ultimate vacuum |

20Pa |

|

heating method |

SD320 heat transfer oil heating |

Temperature control mode |

Self – tuning intelligent PID control |

|

The highest temperature of the table |

180℃ |

Temperature uniformity |

± 1.5 ℃, multi-point temperature control |

|

Operating temperature range |

100~180℃ |

Temperature controllable accuracy |

≤±1℃ |

|

Model |

Automatic photovoltaic laminator for solar photovoltaic cell module BGKJ-Q3622X2 |

|||

|

Device parameters

|

Dimensions |

17000×3100×1800(mm) |

Equipment weight approx |

22T |

|

power supply |

AC380V3 phase 5 lines |

Compress air pressure |

0.6~0.8MPa |

|

|

Compressed air flow |

≥400L/min |

Effective lamination area |

(3600X2200)mm2 |

|

|

Laminated chamber height |

25mm |

Installed capacity |

110KW |

|

|

Normal working power |

60KW |

Vacuum pump evacuation rate |

70L/S |

|

|

Control platform |

touch screen |

Heating the maximum temperature |

180℃ |

|

|

Heating platform |

Per square meter unevenness ≤ 200um |

Temperature range |

30℃–180℃ |

|

|

The entire heating platform |

Uneven temperature distribution ≤ ± 1.5 ℃ |

Temperature control accuracy |

±1℃ |

|

|

Use temperature range |

Room temperature ~ 175 ℃ |

Lamination time |

Depending on the material |

|

|

Take time |

5~8min |

Operating vacuum |

100~15Pa |

|

|

Cover the trip |

300mm |

|

|

|

|

Model |

Automatic photovoltaic laminator for solar photovoltaic cell module BGKJ-Q4624X2 |

|||

|

Device parameters

|

Dimensions |

21500×3200×1800(mm) |

Equipment weight approx |

27.T |

|

power supply |

AC380V3 phase 5 lines |

Compress air pressure |

0.6~0.8MPa |

|

|

Compressed air flow |

≥400L/min |

Effective lamination area |

(4600X2400)mm2 |

|

|

Laminated chamber height |

25mm |

Installed capacity |

121.5KW |

|

|

Normal working power |

62KW |

Vacuum pump evacuation rate |

70L/S |

|

|

Control platform |

touch screen |

Heating the maximum temperature |

180℃ |

|

|

Heating platform |

Per square meter unevenness ≤ 200um |

Temperature range |

30℃–180℃ |

|

|

The entire heating platform |

Uneven temperature distribution ≤ ± 1.5 ℃ |

Temperature control accuracy |

±1℃ |

|

|

Use temperature range |

Room temperature ~ 175 ℃ |

Lamination time |

Depending on the material |

|

|

Take time |

5~8min |

Operating vacuum |

100~15Pa |

|

|

Cover the trip |

300mm |

|

|

|

|

Automatic photovoltaic laminator for solar photovoltaic cell module BGKJ-Q4824X2 |

|||

|

Dimensions |

22300×3200×1800(mm) |

Equipment weight approx |

28.T |

|

power supply |

AC380V3相5线 |

Compress air pressure |

0.6~0.8MPa |

|

Compressed air flow |

≥400L/min |

Effective lamination area |

(4800X2400)mm2 |

|

Laminated chamber height |

25mm |

Installed capacity |

127KW |

|

Normal working power |

65KW |

Vacuum pump evacuation rate |

70L/S |

|

Control platform |

touch screen |

Heating the maximum temperature |

180℃ |

|

Heating platform |

Per square meter unevenness ≤ 200um |

Temperature range |

30℃–180℃ |

|

The entire heating platform |

Uneven temperature distribution ≤ ± 1.5 ℃ |

Temperature control accuracy |

±1℃ |

|

Use temperature range |

Room temperature ~ 175 ℃ |

Lamination time |

Depending on the material |

|

Take time |

5~8min |

Operating vacuum |

100~20Pa |

|

Cover the trip |

300mm |

|

|