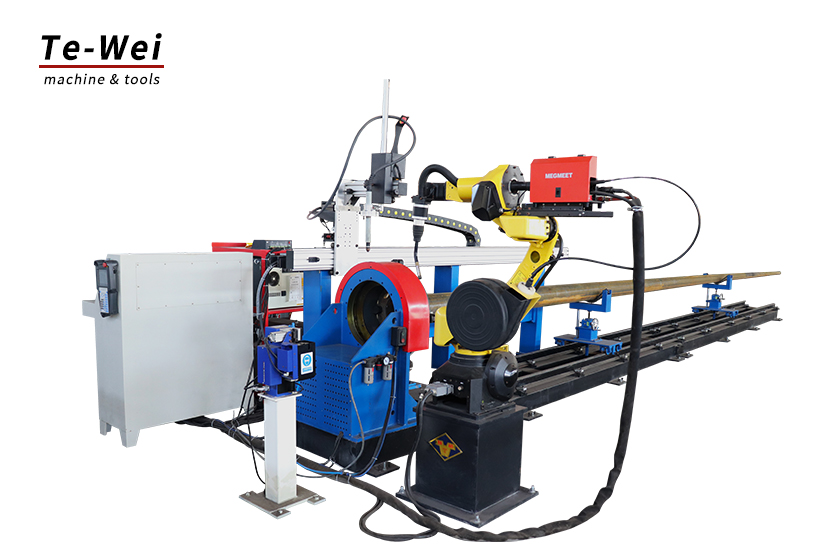

This Machine Adopt Multiple Wire Submerged Arc Welding, Lightless, Speedy, Man Adjusting For The Polygonal Pole. The Power Of The Welding Machine Is From Shanghai Welding Machine Company. Welding Line Was Symmetrical And Slinky. It Has Strong Filter, Forming One Time, And Be With High Welding Efficiency. The Speed Of Welding Achieve 1 To 3 Meters Per Minutes, Is About 3 Times Of The Gas Welding .The Cost Of The Welding Is Lower Than Gas Welding. It Is With Speedy Welding, High Efficiency And Lowest Price In China Light Poles Industry Now.

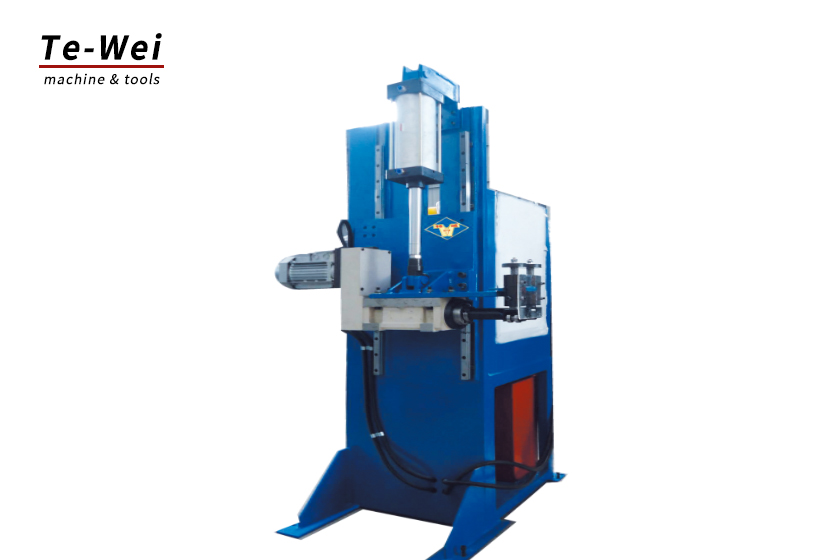

This Equipment Composed By The Board And Bending Mode, With Two Sets Of Molds. Direct Mode Traction Motor Reducer, Will Die On The Pressure In The Round Steel Bar Along The Curved Arc Surface, Simple Operation, Without Heating And Filler, Economic Benefits, Compared With The Industry’s Large-Scale Bending Machine Is Similar Effect, Is Steel Manufacturer Of Equipment Necessary.

| No. | Model | Value | Unit | Note | |

| 1 | Bending Diameter | Φ90 | MM | ||

| 2 | Bending Radius | R500,R700 | MM | 2 Sets Of Round Mould | |

| 3 | Bending Tube Thickness | 4 | MM | ||

| 4 | Motor Power | Model | Y132S-6 | MM | |

| Power | 3 | KW | |||

| Rotate Speed | 960 | RPM | |||

| 5 | Size | L | 3000 | MM | |

| W | 2300 | MM | |||

| H | 620 | MM | |||

| 6 | Weight | 2300 | KG | ||

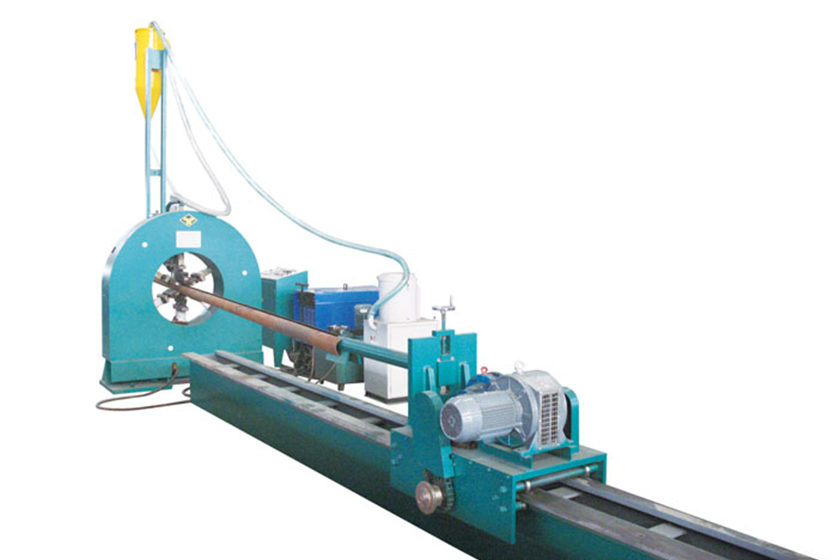

This Machine Steel Tube Adopt Self-Run And The Movement Of The Machine In Order To move The Steel Tube. The Machine Is Fitted With Grinding Polishing Bar, These Grinding Polishing Bars Will Grind And Polish The Surface Of Steel Tube Quickly. It Is Speedy, Efficient, Saving Workers And Energy. It Was The First Choice For Grinding And Polishing Every Pole.

This Machine Is Suitable For The Plate Cutting Processing Specially The Long Plate. Easy Of Operating And Processing Of Optional Length Of The Plate Make The Machine Productive. Pressing The Plate Which Needs To Cut To Walking-Equipment Through The Hydraulic Cylinder And Shear It By Revolving Cutter Accompanied The Movement Of The Walking-Equipment. It Can Also Cuts Taper Plate According To The Request Inclination. Therefore, This Machine Widely Used In The Processing Of Light Pole, Vessel, Metal Structure, Ships, Building, Hardware And So On.

This Machine Composed By Main Machine Head , Tractive Body And Feeding Shelf. Tractive Body Was Moved By Collet In Small Vehicle Nipping The Steel Pole’s Collet. When The Small Vehicle Moved, Driven Steel Pole, From Small Collet To Big Collet, Regularity Moved. The Big Side Of The Steel Pole Was Hold By Feeding Vehicle, Force Automatic Sewing From Head Of Machine To Steerable Wheel. At One Time, The Welding Machine Starts Welding. This Machine Adopt Multiple Wire Submerged Arc Welding, Solder Was Reclaimed Automatic. Welding Line Was Symmetrical And Slinky. It Has Strong Filter, Forming One Time, And Be With High Welding Efficiency. The Speed Of Welding Achieve 2 To 3 Meters Per Minutes, Is About 3 Times Of The Gas Welding .The Cost Of The Welding Is Lower Than Gas Welding. It Is With Speedy Welding, High Efficiency, And Lowest Price In China Light Poles Industry Now.

The whole set of ligh pole machines is for making light poles efficiency and in good quality in factory. The area of workshop:it need about 60000*18000mm two to three rooms,without stacking area and welding area.we can design the plant according to the users actual sizes ,ensure the operating production line.it need the power with about 100 kilowatt.

machines list as below:

1.TW-ZDW43J-6*1800 Cut to length Line

2.TW-ZQ11-6*2400*14000 Steel Plates Diagonally Shearing Production Line.

3.TW-2-WE67K-300/7000 Tandem Press Brake

4.TW-HFH320*5-14000 Automatic Welding Production Line

5.TW-HF600*10-8000 Mechanical Seam Machine

6.TW-W31Y-600*10 Steel Straightened Machine

7.TW-PTW-60 Pole Branch Bending Machine

8.TW- BTSZ-4000/14000 CNC Flame Plasma Cutting Machine

9.TW-ZJP-14000 Electrostatic Spraying Prodcution Line

from the picture you can see clearly what the light pole making progress is?if you have any interested in making poles ,don’t hesitate to contact us. We can help you with workshop layout and workers training ,machines guide installation. we have experience in this field for 20 years. hundreds of factories have setup the light pole production line

This light pole milling machine is used for milling of welding seam ofφ320X5.

Ⅰ.The main parameters of machine

1.Milling head power:2.2KW

2.Type of milling head: XT40

3.Cylinder model:type of 80

4.Suitable for steel pipe diameter: φ60-φ320

5.Wall thickness range: 2-5mm

6.Material:Q235

Ⅱ: light pole milling machineMain component

The machine is composed of bed, base, milling head, pneumatic lifting body, sliding parts and electrical control. The main features are as follows:

1.The whole welding bed can withstand the cutting load and the overall machining accuracy;

2.Precision linear slide rail drives well;

3.Special custom high strength milling head a nice stiffness;

4.The speed of milling head inverter is suitable for the thickness of different plates.

Ⅲ:Main supply accessories

1.Main motor: domestic quality variable frequency motor

2.Bearing: Harbin bearing plant

3.Cutter: domestic quality customized cutting tools.